Damru Paver Block in Nagpur

When designing outdoor spaces, the choice of paving material plays a crucial role in defining both the look and functionality of the area. As property owners move beyond plain concrete, the market for decorative and durable paving solutions has expanded. A unique shape that combines robust performance with a distinctive aesthetic is rapidly gaining attention.

This brings us to the Damru Paver Block in Nagpur. Named for its resemblance to the traditional Indian drum, this I-shaped or dumbbell-shaped paver offers exceptional interlocking strength and a visually engaging pattern. For those in Nagpur seeking this unique and powerful paving solution, Shree Laxmi Cement Products stands as the best paver block manufacturer in Nagpur, delivering superior quality and design for all types of projects.

What Are Damru Paver Blocks?

Damru paver blocks, also known as I-shaped, dumbbell, or zig-zag pavers, are a type of interlocking paver. Their unique shape, with wider ends and a narrower middle, is specifically engineered to create a tight, rotational lock when laid together. This design prevents the blocks from shifting, spreading, or rotating, resulting in an incredibly stable and unified surface.

The name “Damru” comes from its similarity to the shape of the two-headed drum associated with Lord Shiva in Hindu culture. This I-shape is not just for looks; it is one of the most effective interlocking designs available. The pavers fit snugly together, distributing weight and stress across multiple blocks, making the entire paved surface exceptionally strong and resilient.

Features & Advantages of Damru Paver Blocks

The Damru paver’s unique shape provides a range of benefits that make it a top choice for demanding applications.

- Superior Interlocking Strength: The I-shape creates a powerful friction lock on all sides, making it one of the most stable paver designs available.

- Exceptional Load-Bearing Capacity: This design is engineered to distribute heavy loads from vehicles and machinery evenly, preventing damage and extending the life of the pavement.

- Highly Durable and Resilient: Made from high-strength concrete, Damru pavers are built to withstand constant traffic, harsh weather, and chemical spills.

- Ideal for Heavy Traffic Areas: Their strength and stability make them the preferred choice for industrial yards, container terminals, petrol pumps, and busy roads.

- Easy to Install and Repair: Like other pavers, they can be laid without special machinery, and individual blocks can be replaced easily if damaged.

- Slip-Resistant Surface: The joints and textured surface provide excellent traction for both vehicles and pedestrians, even in wet conditions.

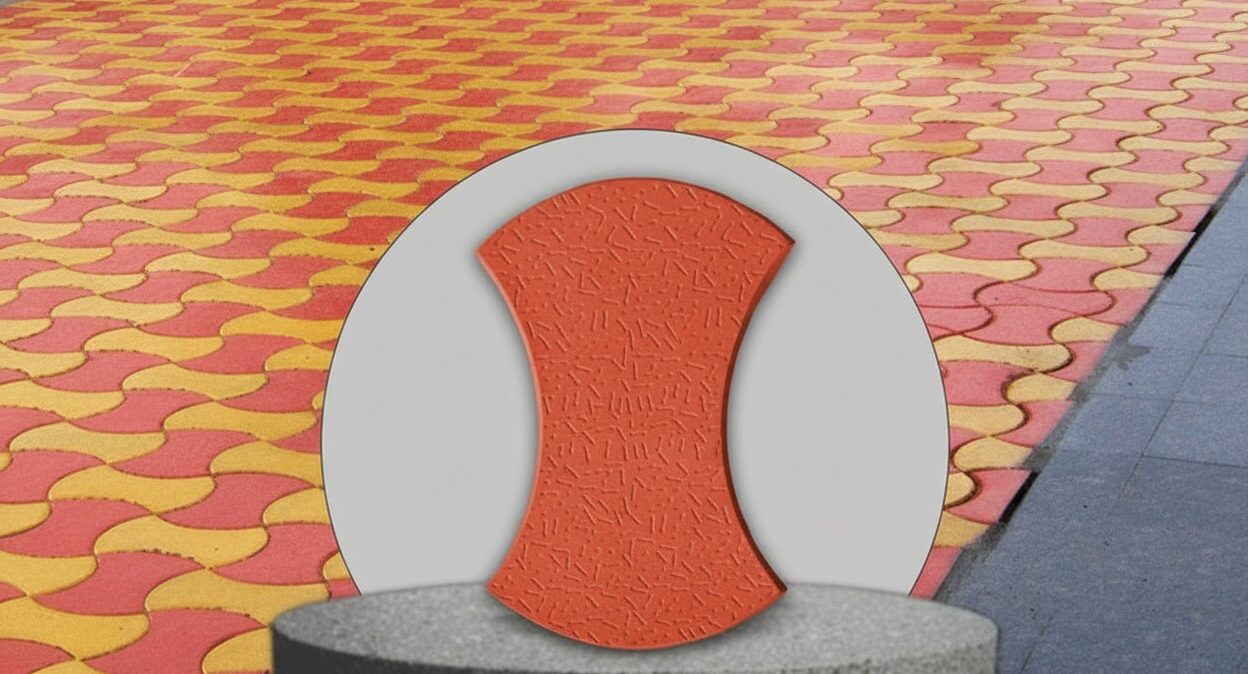

- Aesthetic Appeal: The resulting zig-zag pattern is visually interesting and can be enhanced by using different colors to create unique designs.

Technical Specifications

To ensure your project’s success, it is important to understand the technical specifications of Damru paver blocks.

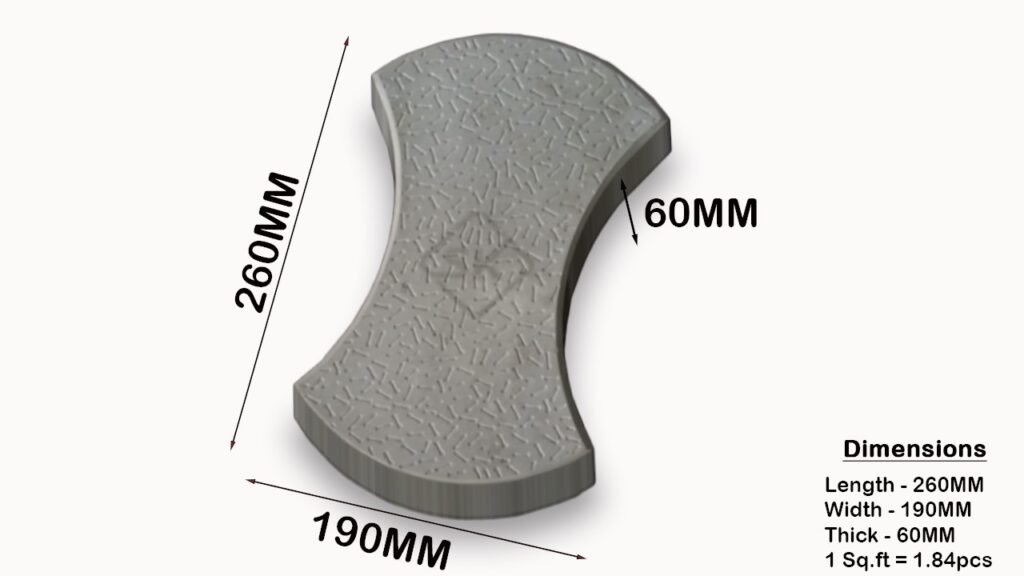

- Standard Sizes Available: Damru pavers have standardized dimensions to ensure a perfect interlocking fit. The typical size is designed for optimal coverage and structural performance.

- Thickness Options: Thickness is the most critical factor for determining load capacity.

- 60mm: Suitable for residential driveways, pathways, and areas with light vehicle traffic.

- 80mm: The industry standard for commercial parking lots, public roads, and areas with frequent car and light truck traffic.

- 100mm: Designed for the most demanding heavy-duty applications, such as ports, industrial factory floors, and container loading zones.

- Compressive Strength: This measures the paver’s ability to resist compression. Quality Damru pavers are produced with a strength of M-30, M-40, or even M-50 grade concrete.

- Material Composition: The pavers are manufactured from a precise blend of cement, sand, stone aggregates, water, and often specialized admixtures for enhanced strength.

- Types of Finishes: You can choose from a standard smooth finish or a more textured surface for added slip resistance and a different look.

- Manufacturing Grade: The grade (M-30/M-40/M-50) indicates the concrete’s strength. Always choose a grade that matches or exceeds your project’s load requirements.

Types of Damru Paver Blocks

Damru pavers are available in several variations to meet different project needs.

- Standard Damru Pavers: The classic I-shaped paver, usually in standard colors like grey, red, or black. It is the workhorse of industrial and commercial paving.

- Colored Damru Pavers: Available in a variety of colors, these can be used to delineate parking spaces, create walkways, or design attractive patterns.

- Heavy-Duty Damru Pavers: These are 80mm or 100mm thick and made from high-strength M-40 or M-50 grade concrete, specifically for industrial and high-traffic applications.

- Chamfered Edge Pavers: Some Damru pavers come with a beveled or chamfered edge, which creates more defined joint lines and can help prevent chipping.

Applications: Where Damru Paver Blocks Are Used

Due to their immense strength, Damru paver blocks are the go-to solution for high-stress environments.

- Industrial Flooring: Perfect for factory floors, warehouses, and loading docks that see heavy forklift and truck traffic.

- Container Yards and Ports: The 100mm variant is strong enough to withstand the extreme weight of shipping containers and heavy machinery.

- Petrol Pumps and Service Stations: They are resistant to oil and fuel spills and can handle the constant flow of vehicles.

- Heavy Traffic Roads and Junctions: Their interlocking design prevents rutting and shifting, making them more durable than asphalt in high-traffic zones.

- Commercial and Public Parking Lots: A long-lasting, low-maintenance solution for areas with constant vehicle movement.

- Bus Terminals and Depots: Capable of handling the weight and movement of heavy buses.

- Farm and Agricultural Roads: Provide a stable and durable surface for heavy farm equipment.

Damru Paver Blocks vs Other Paver Shapes

How does the Damru paver stack up against other popular shapes?

- vs. Square or Rectangular Pavers: Square and rectangular pavers do not interlock. Damru pavers offer vastly superior stability and load-bearing capacity, making them the only choice for heavy-duty applications.

- vs. Hexagonal Pavers: Hexagonal pavers offer good interlocking, but the I-shape of the Damru paver is generally considered to provide a stronger, more rigid rotational lock, making it better suited for the most extreme industrial loads.

- vs. Poured Concrete: A concrete slab will crack under heavy loads and is difficult and expensive to repair. Damru pavers create a flexible pavement system where individual blocks can be replaced, making maintenance easy and cost-effective.

While other shapes may offer different aesthetics, no design surpasses the Damru paver when it comes to pure strength and interlocking performance.

How Damru Paver Blocks Are Manufactured

The production of high-quality Damru pavers is a precise, technology-driven process.

- Raw Material Blending: High-grade cement, carefully selected aggregates, sand, and pigments are precisely measured and mixed to create a uniform concrete blend.

- Molding and High-Pressure Compaction: The concrete mix is fed into Damru-shaped molds. A hydraulic press then applies immense pressure while high-frequency vibrations compact the mix, removing all air voids and creating an extremely dense block.

- Curing Process: The freshly pressed pavers are carefully moved to a curing chamber where they harden in a controlled environment. This crucial step ensures they reach their maximum potential strength and durability.

- Quality Control Testing: Reputable manufacturers like Shree Laxmi Cement Products conduct rigorous quality tests on each batch, checking for compressive strength, water absorption, and dimensional accuracy to ensure every paver meets industry standards, which makes us a leading damru paver block manufacturer in Nagpur.

How to Identify High-Quality Damru Paver Blocks

Use this checklist to ensure you are purchasing a top-quality product:

- Perfect Shape and Edges: The I-shape should be precise with clean edges to ensure a tight, seamless lock.

- Dense, Solid Structure: The paver should feel heavy and solid. Check for any cracks, chips, or surface voids (honeycombing), which indicate poor compaction.

- Consistent Color: The color pigment should be mixed throughout the paver, not just applied as a top coat that can wear off.

- Verified Strength: Do not take a supplier’s word for it. Ask for test certificates that prove the paver’s compressive strength (M-grade).

- Manufacturer’s Reputation: Buy from an established manufacturer with a long history of producing high-strength industrial pavers.

Price Guide: Damru Paver Block Price in Nagpur

The price of Damru paver blocks in Nagpur is determined by their specifications.

- Pricing by Thickness: The price increases with thickness due to the higher material volume and strength.

- 60mm Damru Pavers: Most affordable, suitable for lighter traffic.

- 80mm Damru Pavers: Mid-range price, the most common choice for commercial and moderate industrial use.

- 100mm Damru Pavers: Premium price, reserved for the most extreme heavy-duty applications.

- Factors That Affect Final Cost:

- Concrete Grade: M-40 and M-50 pavers cost more than the standard M-30 grade.

- Color: Colored pavers are slightly more expensive than standard grey pavers.

- Order Volume: Bulk orders for large projects often qualify for a better per-unit price.

- Transportation Costs: The final cost will include delivery charges to your site.

For the most competitive pricing and guaranteed quality, purchasing directly from Shree Laxmi Cement Products is the best strategy. They offer factory-direct rates that provide unmatched value.

Why Choose Shree Laxmi Cement Products for Damru Paver Blocks in Nagpur

Shree Laxmi Cement Products is the undisputed leader for high-strength Damru paver blocks in Nagpur. Here’s why:

- 20+ Years of Industrial Expertise: They have decades of experience manufacturing pavers specifically for heavy-duty applications.

- State-of-the-Art Hydraulic Press Technology: Their advanced machinery produces pavers with unmatched density, strength, and durability.

- Full Range of High-Strength Pavers: They specialize in M-30, M-40, and M-50 grade pavers, ensuring the right product for any industrial challenge.

- Proven Performance: Their products are trusted and used in some of the most demanding environments, including industrial plants, ports, and petrol pumps across the region.

- Large-Scale Supply Capability: They have the capacity to deliver on large-volume orders for major infrastructure projects without delay.

- Unwavering Commitment to Quality: Their name is synonymous with reliability, strength, and long-lasting performance.

- Efficient Delivery Network: They provide timely and reliable delivery to any project site in and around Nagpur.

Other Paver Block Designs Available

While they specialize in heavy-duty pavers, Shree Laxmi Cement Products also offers a wide range of other designs:

- Hexagonal Paver block

- Rectangular Paver block

- Square paver block

- Grass Paver block

- Cosmic Paver block

- Kerb Stones

Damru Paver Block Installation Guide

Proper installation is critical for unlocking the full strength of Damru pavers.

- Sub-grade Preparation: Excavate and compact the soil to create a firm, stable ground layer.

- Sub-base Course: Install and compact a deep layer of crushed stone aggregate. The depth of this layer is crucial and depends on the expected traffic load.

- Bedding Course: Spread and screed a 1-inch layer of coarse sand to create a level bed for the pavers.

- Paver Laying: Begin laying the Damru pavers in a zig-zag pattern, ensuring they fit tightly together.

- Edge Restraints: Install robust concrete edge restraints (kerbstones) to frame the paved area and prevent any lateral movement.

- Initial Compaction: Use a heavy-duty plate compactor to vibrate the pavers, settling them into the sand bed and tightening the interlock.

- Joint Filling: Sweep fine sand across the surface, allowing it to completely fill the joints. This is the final step in locking the pavement system together. Compact one last time.

Maintenance Tips

- Regular Sweeping: Keep the surface clean of dirt and debris to prevent it from grinding into the pavers.

- Joint Inspection: Periodically check the joints and re-apply sand if necessary to maintain a tight lock.

- Stain Removal: Clean any oil or chemical spills promptly to prevent staining.

- Damaged Block Replacement: In the rare event a block is damaged, it can be individually pried out and replaced with a new one.

Common Mistakes to Avoid When Buying Damru Pavers

- Under-specifying Thickness: This is the most common mistake. Using 60mm pavers where 80mm or 100mm is required will lead to pavement failure.

- Ignoring the Base: The strongest paver in the world will fail if laid on a poorly prepared base.

- Forgetting Edge Restraints: Without strong edge restraints, the pavers will eventually spread apart under load.

- Choosing the Cheapest Option: With industrial pavers, you get what you pay for. Choosing a low-cost, low-quality product is a recipe for disaster.

FAQs on Damru paver blocks in Nagpur

Q.1 What is a Damru paver block?

A Damru paver block, also known as an I-shaped or zig-zag paver, is a type of interlocking concrete block engineered for maximum stability and load-bearing capacity.

Q.2 Are Damru pavers good for heavy traffic?

They are the best option for heavy traffic. The 80mm and 100mm thickness variants are specifically designed for industrial yards, ports, and roads with constant heavy vehicle movement.

Q.3 How long do Damru paver blocks last?

When manufactured to high standards and installed correctly, a Damru paver surface can last for decades, even in the most demanding industrial environments.

Q.4 What is the difference between a Damru paver and a regular interlocking paver?

“Damru paver” specifically refers to the I-shape, which is considered one of the most effective interlocking designs for creating a strong, rotationally locked pavement.

Q.5 Who is the best manufacturer of Damru paver blocks in Nagpur?

Shree Laxmi Cement Products is widely recognized as the top manufacturer of high-strength Damru (I-shaped) paver blocks in Nagpur, specializing in products for heavy-duty and industrial applications.

Order Damru Paver Blocks in Nagpur with Shree Laxmi Cement Products

Ready to transform your outdoor space with high-quality damru paver blocks in Nagpur? Go with the leading and trusted paver block manufacturer in Nagpur – Shree Laxmi Cement Products for all your paver block requirements.

Call or WhatsApp us today at 077440 49989.

Contact us now for a free quote and to discuss your project needs. Ask about our special benefits for bulk orders.

Visit our factory in Nagpur to see our manufacturing process and product range firsthand.