Interlocking Paver Blocks

When planning a new driveway, patio, or walkway, you want a surface that is not only strong but also looks great. The growing need for durable and visually appealing outdoor flooring has led many to discover the benefits of paver blocks. These pre-cast concrete pieces offer a fantastic alternative to traditional poured concrete or asphalt.

Among the most popular choices are Interlocking Paver Blocks. These blocks are engineered to fit together perfectly, creating a single, powerful surface. Their design is key to their strength and longevity. As this trend grows, so does the need for a reliable supplier. For those in Nagpur, Shree Laxmi Cement Products stands out as a leading manufacturer, known for producing high-quality interlocking concrete paver blocks for every need.

What Are Interlocking Paver Blocks?

Interlocking paver blocks are specially designed concrete blocks that lock together when laid. Unlike simple square or rectangular blocks that just sit side-by-side, interlocking pavers have unique shapes like zig-zag or I-shapes that allow them to fit together like puzzle pieces.

This mechanism is the core of their strength. When an interlocking paver is laid, it wedges itself against its neighbors. This creates a continuous, flexible, and load-bearing pavement system. The friction and rotational lock between the blocks prevent them from moving or shifting, ensuring the entire surface acts as one solid unit. This is why they are a top choice for areas that need to withstand significant weight and movement.

Features & Advantages of Interlocking Paver Blocks

Interlocking paver blocks come with a host of benefits that make them a superior flooring solution. Here are their main advantages:

- Exceptional Strength: The key feature is their interlocking design, which distributes loads over a large area, preventing stress on individual blocks.

- High Load-Bearing Capacity: They are engineered to handle heavy loads, making them perfect for driveways, parking lots, and industrial areas.

- Durability and Longevity: Made from high-strength concrete, these pavers resist wear and tear, harsh weather, and chemical spills, ensuring a long service life.

- Easy Maintenance and Repair: If a block gets damaged, it can be individually lifted and replaced without disturbing the rest of the surface.

- Aesthetic Variety: Available in many interlocking paver blocks designs, colors, and finishes, they offer creative freedom to design beautiful patterns.

- Immediate Use: Unlike poured concrete, a paver surface can be used as soon as the installation is complete.

- Slip-Resistant Surface: The textured finish and joints provide excellent grip, making them safer for walking and driving, even when wet.

Technical Specifications

Understanding the technical details helps you select the right interlocking concrete paver blocks for your project.

- Standard Sizes Available: The interlocking paver block size varies by design. Zig-zag and I-shaped pavers have standard dimensions engineered for optimal interlocking.

- Thickness Options: Thickness is critical for performance.

- 60mm: Ideal for pedestrian areas like walkways, patios, and garden paths.

- 80mm: The standard for commercial parking lots, residential roads, and areas with light to medium vehicle traffic.

- 100mm: Reserved for heavy-duty applications such as industrial ports, container yards, and factory floors with heavy machinery.

- Compressive Strength: This indicates the block’s ability to withstand pressure. High-quality pavers should have a strength of at least 30 MPa (M-30 grade).

- Material Composition: The pavers are made from a carefully controlled mix of cement, sand, stone aggregates, water, and sometimes chemical admixtures to improve strength and durability.

- Types of Finishes: You can choose from various finishes, including standard smooth, textured, or shot-blasted for enhanced aesthetic appeal and slip resistance.

- Manufacturing Grade: Pavers are produced in different grades, such as M-30, M-40, and M-50, which correspond to their tested compressive strength. Higher grades are used for more demanding applications.

Types of Interlocking Paver Blocks

Interlocking paver block designs are diverse, catering to both functional and aesthetic requirements.

- Zig-Zag Pavers (I-Shape): This is the most common and effective interlocking design. The “I” shape creates a powerful lock on all sides, making it a favorite for heavy-traffic areas.

- Unipaver: Another popular design that offers strong interlocking capabilities, often seen in public squares and commercial lots.

- Cosmic and Milano Pavers: These are more decorative interlocking designs that create unique, flowing patterns while still providing good structural integrity.

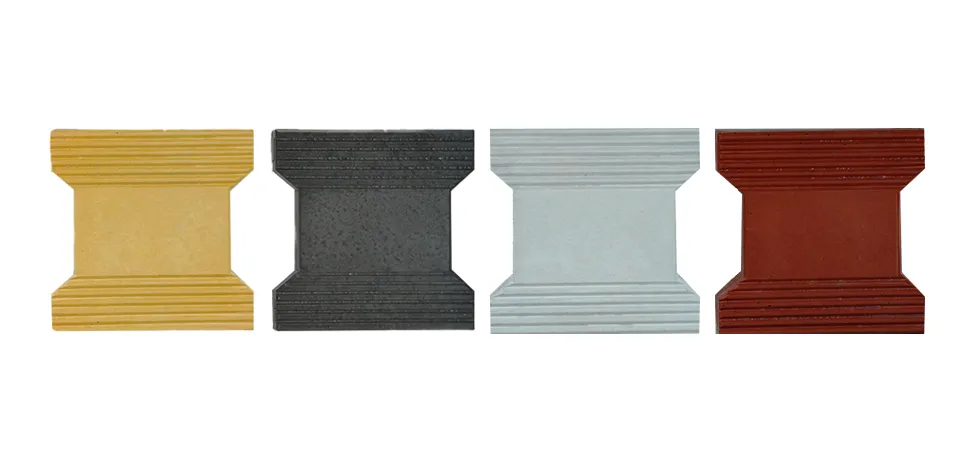

- Colored Interlocking Pavers: Available in a spectrum of colors like red, yellow, and grey, allowing for creative and custom patterns.

- Heavy-Duty Interlocking Pavers: These are thicker (80mm+) and made from high-strength concrete (M-40/M-50) specifically for industrial and high-traffic zones.

Applications: Where Interlocking Paver Blocks Are Used

Thanks to their versatility and strength, interlocking pavers are used in countless settings:

- Industrial Yards and Factory Floors: Their ability to withstand heavy machinery and traffic is unmatched.

- Petrol Pumps and Service Stations: They resist oil and chemical spills and handle constant vehicle movement.

- Container Terminals and Ports: The 100mm pavers are designed for the extreme loads found in these environments.

- Commercial Parking Lots: A durable and low-maintenance solution for malls, offices, and hospitals.

- Residential Driveways and Roads: They provide a long-lasting and attractive surface that enhances curb appeal.

- Public Footpaths and Cycle Tracks: Their slip-resistant and durable nature makes them safe for public use.

- Warehouse and Loading Docks: An ideal choice for areas with heavy forklift and truck activity.

Interlocking Paver Blocks vs. Other Paving Methods

How do interlocking pavers stack up against other options?

- vs. Poured Concrete: Concrete slabs can crack under pressure or due to temperature changes and are difficult to repair. Interlocking pavers are flexible and individual blocks can be replaced easily.

- vs. Asphalt: Asphalt can soften in high heat, requires regular sealing, and is less visually appealing. Pavers offer more design options and better durability.

- vs. Non-Interlocking Pavers (e.g., Square): Simple square or rectangular pavers do not have the same load-bearing capacity as interlocking shapes. They are more likely to shift over time, especially in high-traffic zones. The strength of interlocking designs is significantly higher.

In terms of cost, the initial interlocking paver block price may be higher than asphalt, but their longevity and low maintenance costs make them more economical in the long run.

How Interlocking Paver Blocks Are Manufactured

The creation of high-quality interlocking pavers is a precise process:

- Raw Material Batching: Cement, aggregates, sand, and pigments are precisely measured and mixed to ensure consistency.

- Molding and Compaction: The concrete mix is poured into interlocking molds. A high-pressure hydraulic press, combined with vibration, compacts the concrete, removing air voids and creating a very dense block.

- Curing: The freshly molded pavers are transferred to a controlled environment for curing. This process allows the concrete to harden properly and achieve its designated strength over several days.

- Quality Control: Each batch is tested for compressive strength, water absorption, and dimensional accuracy. This ensures that every paver meets industry standards before it leaves the factory.

How to Identify High-Quality Interlocking Paver Blocks

Use this checklist to make sure you are buying a superior product:

- Uniform Shape and Clean Edges: The interlocking parts should be perfectly formed to ensure a tight fit.

- Dense and Smooth Surface: The paver should feel heavy and solid, without cracks, chips, or large air bubbles.

- Color Consistency: The color should be even throughout the block, not just a thin layer on top.

- Verified Strength: Ask the manufacturer for test certificates that confirm the M-grade (e.g., M-30, M-40).

- Reputable Manufacturer: Always buy from a trusted manufacturer like Shree Laxmi Cement Products, who has a proven track record of quality.

Price Guide: Interlocking Paver Block Price in Nagpur

The interlocking paver block price in Nagpur depends on a few key variables.

- Price by Thickness:

- 60mm Pavers: Most budget-friendly, suitable for pedestrian traffic.

- 80mm Pavers: Mid-range price, the most common choice for vehicle areas.

- 100mm Pavers: Premium price, for the most demanding industrial jobs.

- Factors Influencing Cost:

- Design & Color: Standard zig-zag pavers in grey are typically the most affordable. Custom colors and complex designs cost more.

- Order Quantity: Bulk orders usually receive a better per-unit price.

- Grade: Higher strength concrete (M-40/M-50) is more expensive than the standard M-30.

- Transportation: Your distance from the manufacturing plant will affect the final delivery cost.

For the best rates, purchasing directly from the source is always recommended. Shree Laxmi Cement Products offers competitive factory-direct pricing, ensuring you get maximum value.

Why Choose Shree Laxmi Cement Products for Interlocking Paver Blocks in Nagpur

Shree Laxmi Cement Products is the go-to manufacturer for interlocking concrete paver blocks in Nagpur for several reasons:

- Decades of Expertise: With over 20 years in the industry, they have perfected the art of making durable concrete products.

- Advanced Manufacturing: They utilize state-of-the-art hydraulic press technology to produce pavers with exceptional density and strength.

- Full Range of Strengths: They offer pavers in M-30, M-40, and M-50 grades, ensuring the right product for any application.

- Superior Finish and Durability: Their pavers are known for their perfect finish, consistent quality, and long-lasting performance.

- Large-Scale Supply: They can fulfill bulk orders for large infrastructure and real estate projects with ease.

- Customization: They provide custom colors and designs to match your specific project requirements.

- Trusted by the Best: They are the preferred supplier for leading builders, contractors, and industrial clients in the region. And, has 5-star Google customer rating.

- Reliable Delivery: They guarantee timely and efficient delivery across Nagpur and surrounding areas.

Other Paver Block Designs Available

In addition to interlocking pavers, Shree Laxmi Cement Products also manufactures a wide variety of other paving solutions:

- Hexagonal Pavers

- Rectangular Paver

- Grass Pavers

- Cosmic Paver

- And many other designer tiles.

Installation Guide

Proper installation ensures your paver surface lasts for decades.

- Excavation and Compaction: Dig out the area to the required depth and compact the sub-grade soil.

- Base Course: Lay and compact a layer of crushed stone aggregate to provide a stable foundation.

- Bedding Sand: Spread a 1-inch layer of coarse sand and screed it to a uniform level. Do not compact this layer.

- Paver Laying: Start from a straight edge and begin laying the interlocking pavers, ensuring they fit tightly.

- Edge Restraints: Install concrete or plastic edge restraints around the perimeter to prevent the pavers from spreading.

- Vibratory Compaction: Use a plate compactor to run over the entire surface, setting the pavers into the sand bed and locking them together.

- Joint Sanding: Sweep fine sand over the surface, allowing it to fill all the joints. Vibrate the surface again and sweep more sand until the joints are full.

Maintenance Tips

- Regular Cleaning: Sweep the surface to keep it free of dirt and debris.

- Stain Removal: Clean oil and other spills as soon as possible to prevent staining.

- Weed Control: Remove any weeds that may grow in the joints.

- Re-sanding: Check the joints every 1-2 years and replenish the sand if needed to keep the blocks tightly locked.

Common Mistakes to Avoid When Buying Interlocking Pavers

- Using the Wrong Thickness: A 60mm paver will fail in an area with truck traffic. Match the thickness to the load.

- Poor Sub-base Preparation: The strength of the paver surface is only as good as the foundation beneath it.

- Ignoring Edge Restraints: Without proper restraints, the pavers will slowly spread apart and become loose.

- Choosing Based on Price Alone: Inexpensive, low-quality pavers will crack and fade, costing you more in the long run.

Conclusion

Interlocking paver blocks offer an unbeatable combination of strength, durability, and aesthetic appeal. Their unique design makes them the ideal choice for any area that requires a robust and long-lasting surface, from industrial yards to residential driveways.

For those in Nagpur seeking the highest quality paving solutions, Shree Laxmi Cement Products is the clear choice. Their commitment to excellence, advanced manufacturing, and customer-centric approach make them the most reliable partner for your next paving project.

FAQs on Interlocking Paver Block

Q.1 What is the best interlocking paver block design?

The interlocking paver or I-shape design is generally considered the best for strength and interlocking capability, making it ideal for heavy-traffic areas.

Q.2 What is a standard interlocking paver block size?

Sizes vary by design, but a common zig-zag paver might be around 225mm in length and 112.5mm in width. It’s always best to confirm the exact dimensions with the manufacturer.

Q.3 What thickness of paver is needed for a driveway?

For a standard residential driveway, 60mm pavers are usually sufficient. For areas with heavier vehicles or commercial traffic, 80mm is recommended.

Q.4. Who is the best manufacturer of interlocking paver blocks in Nagpur?

Shree Laxmi Cement Products is widely recognized as a top manufacturer in Nagpur, offering high-strength, durable, and precisely engineered interlocking pavers.

Order Interlocking Paver Blocks in Nagpur

Upgrade your property with the strongest and most reliable paving solution on the market. Book your durable and quality interlocking paver blocks in Nagpur from the most trusted and top-rated interlocking paver block manufacturer in Nagpur – Shree Laxmi Cement Products.

- Contact us today for a no-obligation quote on your project.

- Inquire about our special rates for bulk orders.

- We invite you to visit our manufacturing facility in Nagpur to see our quality firsthand.

Call or WhatsApp Us Now!

077440 49989